1 / Importance of traceability

Traceability is used above all to ensure the quality of a product.

It makes it possible to control the good progress of all the stages of the manufacture of the product: to validate the conformity of the cooking and the cooling of food and raw materials (this is what is called pasteurization)

This avoids food contamination and the resulting diseases, but it also prevents the accelerated deterioration of products ...

2 / Pasteurization

For a good pasteurization, there are different steps to be followed scrupulously. First of all, you have to cook above 80 ° C for 3 minutes.

Then, the products are cooled as quickly as possible so as to remain in the critical zone of 63 ° C to + 10 ° C for the shortest time possible. This interval favors microbial activity and promotes the rapid multiplication of most germs ...

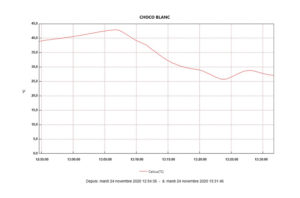

3 / The temperature recorder on our pastocookers

The interest of the pastocooker is the presence, on the same machine, of the cooking and cooling mode. This avoids handling the preparations and thus the likelihood of them deteriorating.

We offer an optional temperature recorder to automate temperature readings and ensure proper cooking and pasteurization of products.

We choose the temperature measurement interval and we extract the data daily on computer to have an excel file and graphical curves. This allows to have writings and statistics and to better understand the cycles that we engage.

4 / Annual calibration on our machines of temperature probes (PLC and regulator)

Once a year, you will need to compare the temperature displayed on the two screens, and then take the measurement after putting the machine on stirring for 10 minutes. We can thus check the consistency of the three cycles.

by

by